Optimization Comprehensive Traceability Mineral

Traceability Mineral

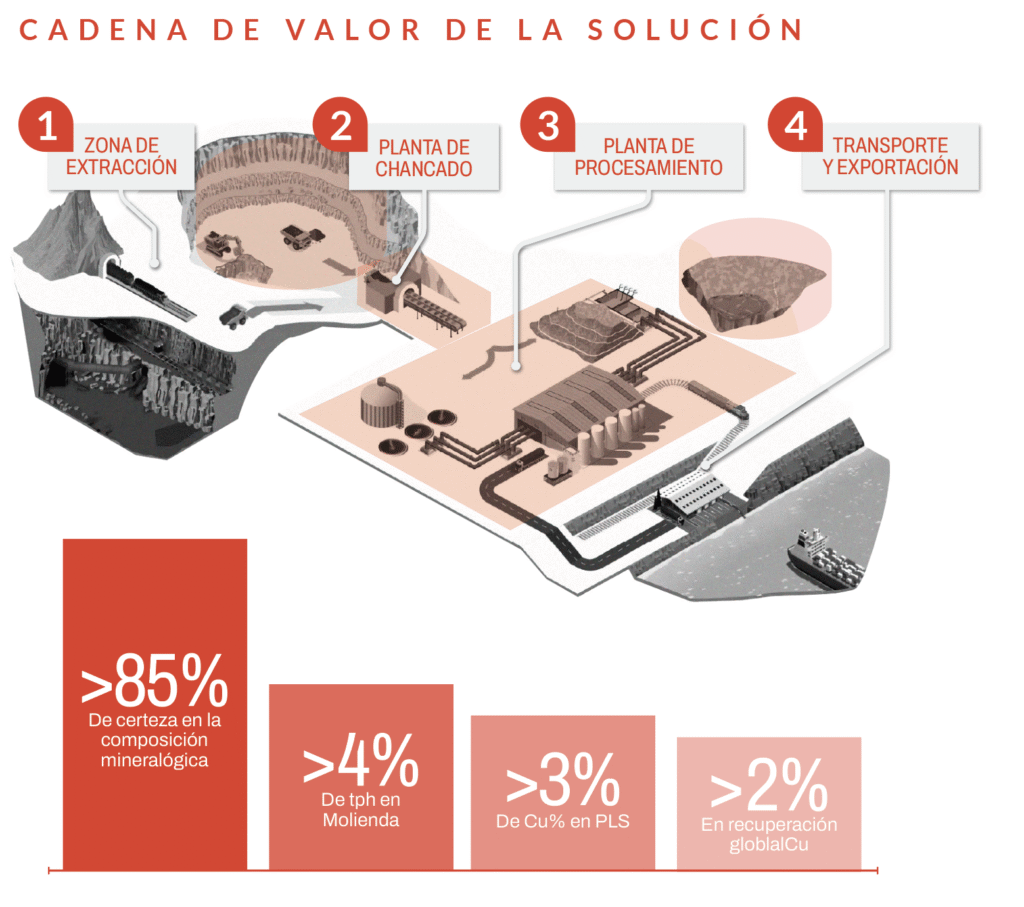

Solution of advanced analytical modeling of the mineral from the point of extraction to plant/hydrometallurgy to reduce variability, optimize mixing and supplies and to raise the global recovery. Integrates operational data and laboratory to deliver recommendations and alerts to align the plan geometalúrgico with the daily execution.

Problem it solves

- Variability mineral that affects TPH, energy consumption and quality.

- Mixtures of sub-optimal and over/under-dosing of inputs.

- Lack of visibility of the “voyage of the mineral” and its downstream impact.

- Difficulty to adjust the plan when changing real-world conditions.

Expected impact (KPIs)

The traceability mineral reduces the variability and losses, anticipated attributes geometalúrgicos from mine to hydrometallurgy (mass balance, and residence times), optimizes the mixture and the use of inputs, lift the TPH in grinding and the stability of the process, improves the Cu% in PLS, and the global recovery, and delivery monitoring and newsgathering with alerts to adjust the operating plan in real-time.