Digital Twins in the process of lithium

Digital Twins

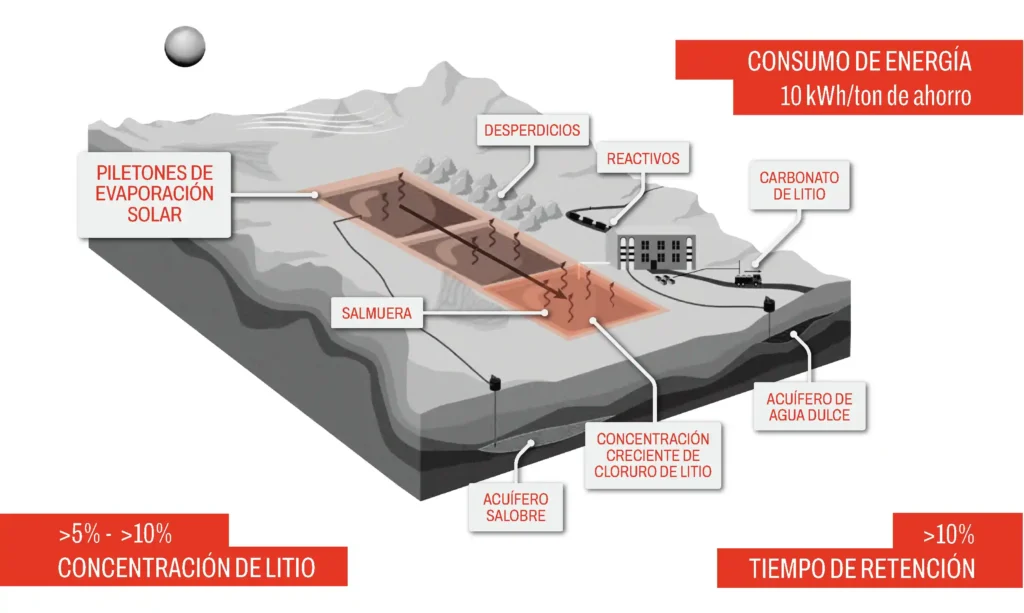

A Digital Twin with AI optimizes evaporation ponds, lithium, integrating meteorological variables, brine and operational. Reduces time, increases concentrations and prevents sedimentation through real-time monitoring, simulations of reaction and predictive analysis. Generates operational recommendations to adjust parameters and to maximize the recovery, with continuous control is integral.

Optimization of evaporation ponds with AI

We model and monitor wells in real time (brine, temperature, humidity, and concentration), we simulate reactions and apply predictive analysis to reduce time, increase concentrations and to avoid sedimentation, aligning operation and quality.

REAL-TIME MONITORING

On the basis of the sensors and data existing in the evaporation ponds, collect real-time data on levels of brine, temperature, humidity, and concentration of lithium, allowing you to visualize these data in a panel of centralized control

MODELING AND SIMULATION

Through the creation of mathematical models, based on data, to simulate the reactions that occur in the evaporation ponds. Perform multiple simulations to test different scenarios, such as changes in climatic conditions, or in the levels of brine, without interrupting the real-world operations.

PREDICTIVE ANALYSIS

Through the implementation of Algorithms of Machine Learning, analyze historical data and predict future trends, as the rate of evaporation and the concentration of lithium.

TO GENERATE RECOMMENDATIONS FOR OPERATION

To continually adjust the process parameters to maximize the recovery of lithium. On the basis of historical data, to generate recommendations for operation of the variables actionable greatest impact they have on the better result of the process

Twins Digital that turn data into decisions

Twins digital integrated sensors, SCADA, laboratory and climate replicate the process, simulate scenarios, predict deviations and issue operational recommendations traceable. With this reduced cycle times and energy, elevated concentrations and recovery, prevent sedimentation and lower variability. Deliver real-time visibility, auditing, and governance of data, facilitating riders, scaling stages and measurable impact on KPIs critical to safety, quality and productivity.